Heat-resistant and high-temperature steels are metallic materials that can be used at higher temperatures and have high stability against temperature-related plastic creep and changes in material properties. The maximum operating temperature is approx. 400 to approx. 620 °C; in the upper temperature range, these are referred to as high-temperature steels. Heat-resistant and high-temperature steels should be able to withstand the highest possible mechanical loads at elevated temperatures and have sufficient resistance to high-temperature corrosion. The evaluation criterion for strength at high temperatures is, for example, the 1% time strain limit Rp1/1000. The 1% time strain limit Rp1/1000 indicates the stress at which a permanent strain of 1% is present after 1000 hours.

While the mechanical strengths of conventional unalloyed steels drop significantly with increasing operating temperature, the strength properties of heat-resistant steels are significantly improved at higher temperatures through alloying measures. The steels are mainly alloyed with chromium, molybdenum, vanadium and tungsten, which gives these steels good creep resistance and sufficient structural stability.

The choice of steels depends on their operating temperature, the mechanical stresses, the area of application and the intended use. The group of heat-resistant and high-temperature steels includes numerous different types of steel.

Low-alloy, heat-resistant steels for application temperatures in the lower temperature range are used in normalised or martensitic-bainitic quenched and tempered condition. These steels are strengthened by carbides and carbonitrides of the elements Cr, Mo,W,V and Nb.

High-temperature steels for use in the upper temperature range contain 9 to 12 % Cr and are quenched and tempered. These steels are also strengthened by carbides and carbonitrides of Cr,Mo,W,W and Nb. However, through special alloying and heat treatment, more thermally stable precipitates are achieved, primarily Nb carbonitrides and improved scaling resistance.

As the precipitates gradually coarsen or dissolve again due to creep stress, the strengthening mechanism looses its effectiveness and there is an upper limit temperature for the application of normalised or quenched and tempered steels. Austenitic steels based on Cr-Ni show a significantly higher creep resistance at temperatures above 600°C and are sometimes used semi-hardened or precipitation-hardened.

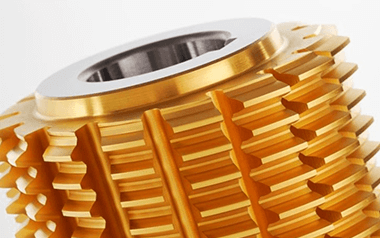

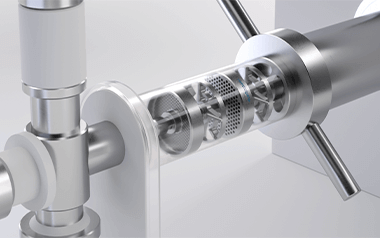

The application of heat-resistant and high-temperature steels is closely related to the development of energy technology and is in the field of steam and gas turbines, petrochemicals and e.g. valves in combustion engines. The steels are selected according to the thermal design, taking economic efficiency into account. For the highest thermal loads, it is sometimes necessary to use Ni-based alloys.