Search

-

Corrosion resistant and non magnetic steel

- Ferritic and martensitic steels, incl. precipitaion hardening steel

- Austenitic steels

- Duplex and super duplex stainless steels

-

Engineering Steels

- Bearing steels

- Case hardening steels

- Heat treatable steels and precipitation hardening steels

-

Additive Manufacturing Powder

- Fe-based alloys

- Ni-based alloys

-

Automotive

- Automotive Racing

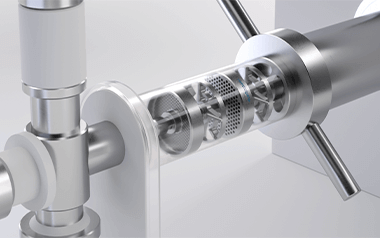

- Injection Components

- Oth. Automotive components (Turbochargers, Piston Rings, Sensors, etc.)