Search

-

Plastic mould steels

- Hardenable corrosion resistant steels

-

Corrosion resistant and non magnetic steel

- Ferritic and martensitic steels, incl. precipitaion hardening steel

- Austenitic steels

- Duplex and super duplex stainless steels

-

Engineering Steels

- Bearing steels

- Case hardening steels

- Heat treatable steels and precipitation hardening steels

-

Additive Manufacturing Powder

- Co-based alloys

- Fe-based alloys

- Ni-based alloys

- Ti-based alloys

-

Other Products

- Precision Flat Ground

- EDM

-

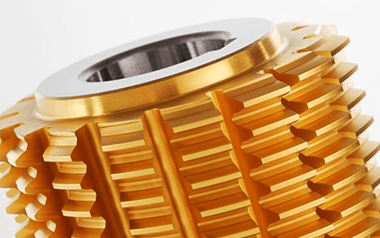

Automotive

- Automotive Racing

- Injection Components

- Oth. Automotive components (Turbochargers, Piston Rings, Sensors, etc.)